- The UDCSolidos team, from the Interdisciplinary Center for Chemistry and Biology of the University of A Coruña (CICA), seeks to replace current heating and cooling components, which are harmful to the environment, with more sustainable and efficient ones.

- The group has just received Ignicia support, a program promoted by the Galician Research Agency (Again) to transfer basic science to industry.

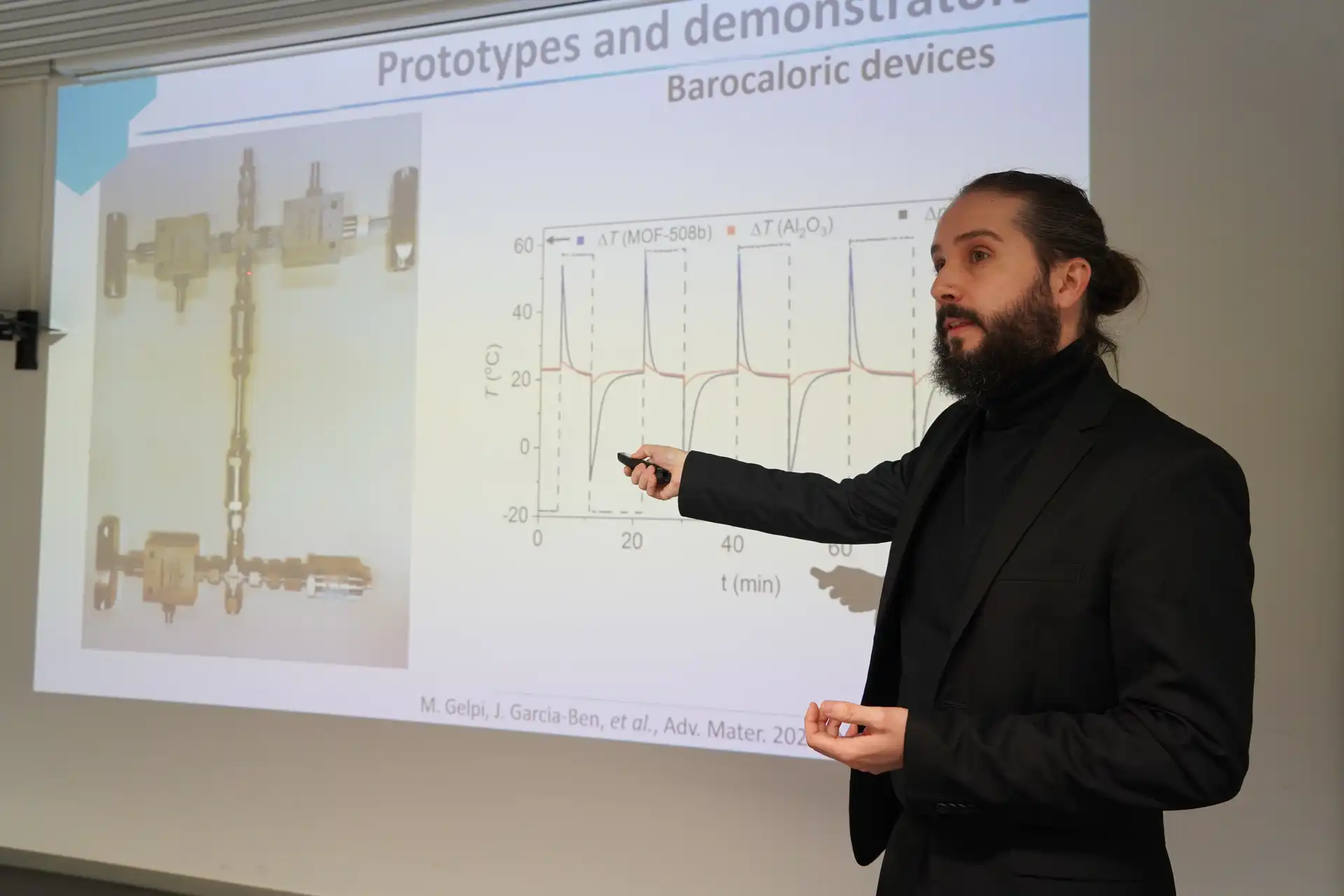

A Coruña, February 20, 2024.- Researchers from the Nanoscience and Technology area of CICA have been studying for years the properties of certain materials that can meet the current challenge of cooling and heating homes and large surfaces while being less polluting. In their latest study, published in the journal Advanced Materials, they detail a new property of organometallic reticular compounds (MOFs): their respiro-caloric capacity allows these materials to regulate temperature by applying pressure to their structure. The next step, they comment in the UDCSolidos group, is to transfer this basic knowledge to industry.

Energy efficiency has gained great importance in recent years as one of the lines of action to mitigate our impact on the planet. For the European Union, this efficiency must be sought in all areas, both in the individual use of energy in our homes and in the public sphere. Currently, the systems used to cool or heat our homes and other large enclosed spaces use hydrofluorocarbons, commonly known as fluorinated gases. It is known that many of these gases, which were implemented in industry in the 1980s to prevent the deterioration of the ozone layer, have a global warming potential of the order of a thousand times greater than the potential of CO₂, which means that one ton of these gases is equivalent to 1,000 tons of carbon dioxide.

Due to this global warming potential, it is imperative for the European Union to replace these fluorinated gases with other compounds. For this reason, since 2014 there has been a regulation that aims to eliminate their use by up to 80% by the year 2050. In addition, the European Energy Efficiency Directive of 2023 seeks to promote the replacement of combustion boilers with heat pumps, which also use refrigerant gases. With this objective in mind, researchers from the UDCSolidos group have been searching for years for new materials that are less polluting, economically viable and capable of meeting our needs.

Juan Manuel Bermúdez García, Ramón y Cajal researcher at the Group with support from the UDC-Inditex InTalent program, explains: “We find ourselves in a context, also accelerated by the war in Ukraine, in which we want to stop depending on natural gas. We must stop doing so from 2026, and start promoting the use of heat pumps. The problem? That today only 2% of all homes and all buildings that are within countries belonging to the European Union use these systems.” What’s more, this transition is more complicated if we take into account that these heat pumps use the aforementioned fluorinated gases.

Recently, these researchers published a study in which they seem to have found an answer, and in this case the solution is due to a surprising characteristic: the respiro-caloric property of a hybrid compound (metallic and organic), the MOF-508b. According to Bermúdez García, these materials would work in a similar way to our lungs, swelling when they receive CO₂ and deflating when they expel it. In the middle of this process, a change would occur in the structure of the material in addition to CO2 absorption processes, resulting in a thermal change.

This fundamental “breathing” mechanism as well as the MOF-508b compound were already known. However, the respiro-caloric properties of temperature change were described for the first time in this CICA laboratory.

It was precisely in this same laboratory that Perovskites were discovered seven years ago, a Galician term coined to define a family of solid materials that presented barocaloric properties, that is, cooling effects through structural changes due to pressure, but without absorbing gases: “Until then, the barocaloric materials that were being investigated were only capable of altering the temperature if they were subjected to pressures of the order of 1,000 bar. To give you an idea, in nature we only find that pressure at the deepest point on the planet, the Mariana Trench. Imagine the pressure that comes from having an 11-kilometer column of water above your head… it was not viable to implement it in a cooling system like a refrigerator, where the material must be able to operate with a pressure of around 30 bar”, summarizes Dr. Bermúdez García. However, the UDCSolidos team managed to synthesize perovskite and produce changes in temperature with it by applying only 70 bar of pressure. The results were very promising, but there was still an obstacle: “Systems based on these materials were not capable of cooling sufficiently, only a couple of degrees,” recalls the researcher.

Now, their finding on the respiro-caloric properties of MOF-508b seems to circumvent this technical difficulty, since this material requires a much lower pressure, of only 16 bar, and is capable of cooling down to -10ºC. In addition, this material can also heat up to 56ºC, so it would be useful for both cooling and heating systems.

As always, in science, great discoveries are made in teams. In this case, the UDCSolidos group, led by María Antonia Señarís-Rodríguez, had the close collaboration of other researchers from the University of A Coruña itself, such as the Thermal and Rheological Properties research group of Ramón Artiaga and Jorge López Beceiro, with the Energy Engineering group of Álvaro Baaliña, and with researcher Sonia Zaragoza, an industrial engineer with extensive experience in companies in the refrigeration sector.

According to Bermúdez García, “now our next step is to implement all this knowledge and take it to the industry. To do this we need, among other things, to expand the production of our materials on a medium scale, identify the most suitable market for our refrigerants, and build a prototype that can operate in real conditions.”

The group received support from the Galician Innovation Agency (GAIN) within the “Ignicia, proof of concept” program. Ignicia promotes the development of commercial applications based on research carried out in centers in Galicia: “On this occasion, we were granted 433,000 euros within a two-year project, and thanks to this call we will be able to mature the technological development, launch a business plan, and show our technology at specialized fairs in the sector or meetings with companies. In the future, our idea is to be able to reach licensing agreements with multinational companies or even establish a company ourselves based on this technology,” adds the researcher.

Photo: Juan Manuel Bermúdez García, Ramón y Cajal researcher with the support of the UDC-Inditex InTalent program of the UDCSolidos team, of the Interdisciplinary Center for Chemistry and Biology of the University of A Coruña (CICA)

Posted by:

UDC Communication Office